Underhood Analysis | Region: INDIA

Industry: Automotive

CLIENT PROFILE:

- Leading Construction Equipment OEM in India.

OBJECTIVE:

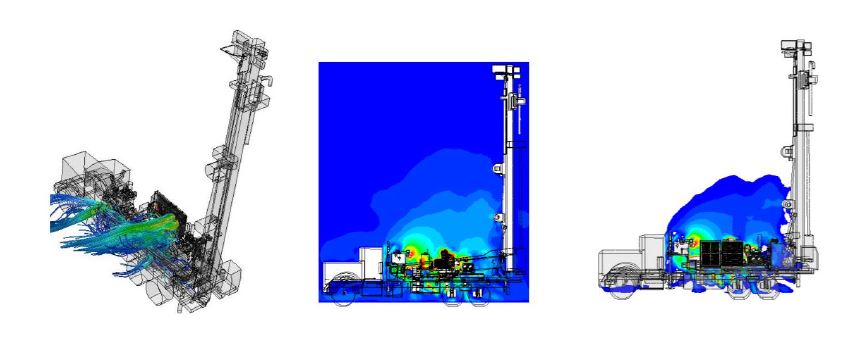

- Underhood system consists of various components like Cooler, Fans, Compressor, Engine, Motor, Alternator, Fuel tank, Electrical Unit, etc. Cooler fans should able to supply sufficient air flow to the various components of Underhood system and maintain the temperature below critical limit. Multiple coolers with heat load applied on it, Engine heat load & Exhaust system heat load makes Underhood system very complex to study. CFD helps in understanding amount of flow rate going to various components, flow pattern inside canopy, identification of flow short circuiting, locating recirculation & dead regions and thermal distribution inside the Underhood system.

Business Challenge

- Modeling of heat dissipation within various Units due to forced convection

- Modeling of combined Convection, Conduction & Radiation.

- Underhood involves lot of components and meshing them needs to be strategized.

Milestone Solution

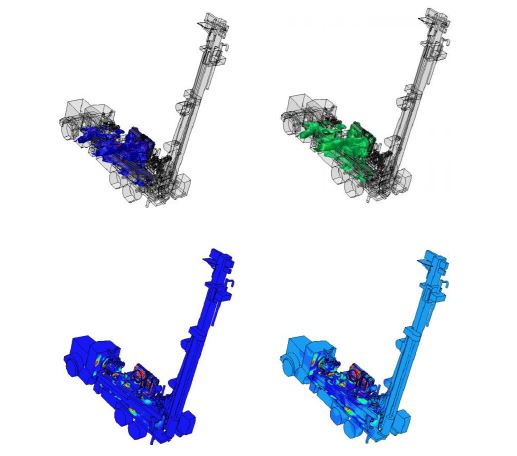

Flow & thermal simulation of the complex Underhood system is carried out. Consideration of radiation load over canopy surfaces along with the conduction & convection within canopy made the thermal system very complex for obtaining the heat balance. Flow short circuiting paths, recirculation dead regions, temperature distribution inside canopy and temperature profile on engine, cooler, intake & exhaust systems are observed. Cooler fan flow rates are compared with minimum flow requirement criteria. Also the skin temperature of various components of Canopy is checked and compared with critical limits.

BUSINESS IMPACT DELIVERED:

- Prediction of Cooler fan flow rates in presence of overall resistance of complete Underhood system.

- Virtual testing of Underhood system under various operating scenarios.

- Predicted appropriate design modifications as per CFD results & thermal requirement.

- Reduced number of trials for hassle free operation under various scenarios.