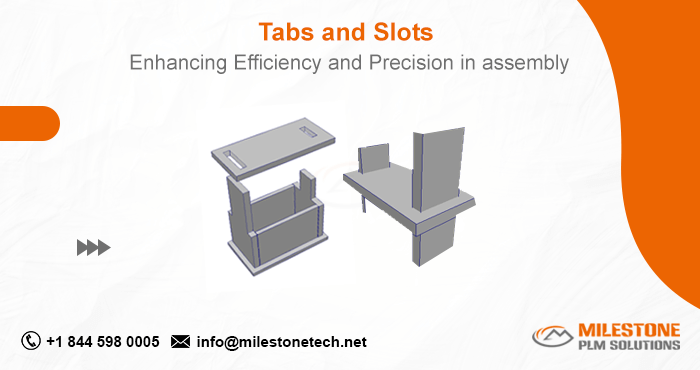

Tabs and Slots: Enhancing Efficiency and Precision in assembly

In the realm of manufacturing and assembly, precision and efficiency are paramount. The quest for improving these aspects has led to the evolution of various design techniques and innovations. Among these, the use of tabs and slots stands out as a simple yet highly effective method for enhancing both the accuracy and speed of assembly processes. This blog delves into the benefits and applications of tabs and slots, illustrating how they can transform assembly operations in diverse industries.

Understanding Tabs and Slots

Tabs and slots are fundamental components in assembly design. Essentially, tabs are protruding parts designed to fit into corresponding slots in a mating piece. This interlocking feature allows components to be securely joined without the need for additional fasteners such as screws or nails. The simplicity of this design not only streamlines the assembly process but also enhances the structural integrity of the assembled product.

The Advantages of Tabs and Slots

Improved Efficiency

One of the most significant advantages of using tabs and slots is the increase in assembly efficiency. Traditional assembly methods often require multiple steps, including aligning, fastening, and securing components. With tabs and slots, components can be quickly and easily aligned and joined, drastically reducing assembly time. This efficiency is particularly beneficial in high-volume production environments where time savings translate directly into cost reductions.

Enhanced Precision

Precision is critical in manufacturing, and tabs and slots provide a straightforward solution to ensure accurate alignment. The interlocking design naturally guides the components into the correct position, reducing the risk of misalignment. This precise fit minimizes gaps and ensures that the final product meets stringent quality standards. For applications where exact measurements are crucial, such as in aerospace or electronics, this precision is invaluable.

Cost Savings

The use of tabs and slots can lead to significant cost savings. By eliminating the need for additional fasteners, manufacturers can reduce material costs and lower assembly labor expenses. Furthermore, the reduced assembly time decreases overall production costs. In addition, the simplicity of the design can lower manufacturing costs associated with tooling and production setups.

Durability and Strength

When designed correctly, tabs and slots can enhance the structural strength of an assembly. The interlocking nature of the design distributes stresses more evenly across the assembled parts, which can improve the overall durability of the product. This is particularly advantageous in applications where the assembled product will experience high stress or heavy loads.

Ease of Disassembly

While tabs and slots are designed for efficient assembly, they also facilitate easy disassembly. This feature is beneficial for products that require maintenance or repair. Being able to disassemble and reassemble parts without damaging them or using special tools enhances the product’s longevity and serviceability.

Applications Across Industries

Tabs and slots find applications across a broad spectrum of industries, each benefiting from the efficiency and precision they offer.

Consumer Electronics

In the consumer electronics sector, tabs and slots are used to assemble components of devices such as smartphones, tablets, and laptops. The precision provided by this method ensures that electronic components are securely held in place, which is crucial for maintaining device functionality and reliability.

Automotive Manufacturing

The automotive industry employs tabs and slots in the assembly of various vehicle parts. From interior trim panels to engine components, this design technique ensures that parts fit together correctly and withstand the rigors of operation. The ease of assembly and disassembly also aids in automotive repairs and maintenance.

Furniture Production

In furniture manufacturing, tabs and slots are used to create flat-pack furniture that is easy to transport and assemble at home. This approach not only simplifies the assembly process for consumers but also reduces shipping costs and improves product durability.

Aerospace Engineering

Aerospace components require the highest levels of precision and strength. Tabs and slots are used in the assembly of various aircraft parts, where the interlocking design helps maintain structural integrity under extreme conditions. The ability to achieve precise fits ensures that aerospace assemblies meet stringent safety and performance standards.

Packaging and Point-of-Sale Displays

Tabs and slots are also employed in the design of packaging and point-of-sale displays. In these applications, the interlocking design allows for easy assembly and disassembly, which is particularly useful in retail environments where displays may need to be frequently updated or repositioned.

Design Considerations

While tabs and slots offer numerous benefits, effective implementation requires careful design consideration. Here are a few key factors to keep in mind:

- Material Selection: The choice of material can impact the strength and durability of tabs and slots. Ensure that the materials used can withstand the stresses encountered during assembly and use.

- Tolerance and Fit: Precision in the design of tabs and slots is crucial. Ensure that tolerances are correctly specified to achieve a snug fit without excessive force.

- Manufacturing Processes: The manufacturing process used to create tabs and slots should be capable of achieving the required precision. Consider factors such as tooling and production techniques when designing these features.

Conclusion

Tabs and slots are a testament to how simple design solutions can significantly enhance efficiency and precision in assembly processes. By integrating these features into product designs, manufacturers can achieve faster assembly times, reduce costs, and improve product durability. From consumer electronics to aerospace engineering, the applications of tabs and slots are vast and varied, demonstrating their versatility and effectiveness across industries. As manufacturing continues to evolve, the principles of tabs and slots will remain a valuable tool for achieving high-quality, efficient, and cost-effective assembly solutions.

Follow Milestone PLM Solutions for Mechanical Industry Updates, CAD Tips and Global Mechanical News.

Milestone PLM Solutions with its exclusive delivery center in India is a global CAD, CAM & FEA services outsourcing partner serving the needs of the Mechanical, Millwork and Automotive industry since 2004. MILESTONE focuses on the unique needs of clients and believes in tackling real-life problems with efficiency, smooth and ease.

The MILESTONE team can assist you with Product Design, 3d Modeling, Drafting & detailing, Reverse Engineering, FEA Analysis and more. We support multiple software including AutoCAD, SolidWorks, Catia, NX, Inventor, Solidedge & Ansys etc. Our approach is to provide a dedicated team for each customer over ongoing project and deliver the quality output consistently.

With our state of art technology and large talent pool of Engineers, we are developing best in class solutions for our customers across the globe. We align with your culture and values to form unbreakable partnerships and are primed for success with over 100 employees and 150 customers in the US, Europe, India, and Asia.

You can email us at info@milestonetech.net and can log in to our website www. milestonetech.net to know more about our services and our work portfolio or contact us on +1-844-598-0005