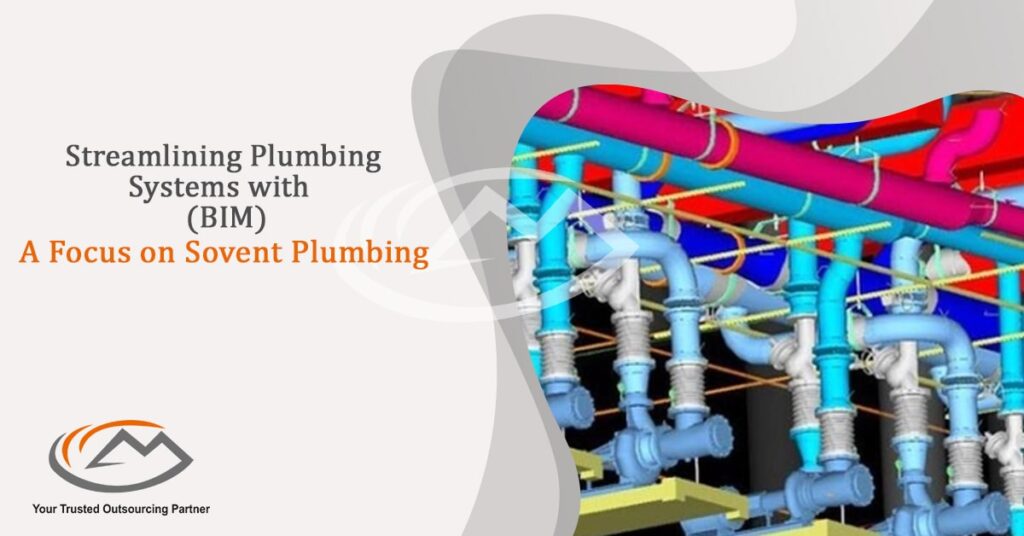

Streamlining Plumbing Systems with Building Information Modeling

The Single Stack System

Huge properties typically need special plumbing systems that make the process of handling their drainage needs and supplying fresh oxygen easier. Since our focus is on performance, we introduced Sovent to revolutionize how these systems are handled at colossal properties. This system both manages drainage waste and vents as one process in contrast to the traditional two-stack system that we’re currently used to seeing. By implementing Building Information Modeling, the construction company successfully streamlining plumbing systems, leading to improved efficiency and cost savings.

Two-stack systems enable the utilization of water waste for irrigation purposes. One pipe in the stack serves as the drainage point while the other serves as a ventilation pipe. Single-stack systems, on the other hand, are widely preferred by MEP BIM Services these days since they’re more advanced and easier to install. The stack system, whether monolithic or modular, minimizes cost and energy consumption. The single stack system reduces repair costs, as there are fewer pipes to repair or rebuy. It also prevents pressure losses from exceeding +/- one-inch of water column in all drainage systems.

The System Contains

- A vertical stack designed to allow the environment to flow through.

- Horizontal branches are attached to each fixture,

- Sovent Aerator fittings can be used to make your home water-efficient and easy to irrigate.

- The modern and versatile fitting designed for drying

Hubless fittings make it easy to assemble new systems without any hassle. And our dual-sided aerator and de-aerator utilizes these hubless connections for assembly management, preserving the acoustical values.

Benefits of Single Tag System

- Takes up less space because there is one stack and no change in required vents

- It’s easier to design a website with fewer pieces of equipment to review.

- In the rewritten sentence you have removed all the extra words that are not necessary, and have replaced them with words that relate better to the topic.

- Extremely affordable.

- Requires less of a pipe and fittings, which means less to buy, transport, and store.

- Because it’s easier to test for contaminants with less water and pipe, this system minimizes testing time.

- Determines the fastest and most effective way to remain unprotected with a minimal amount of penetrations.

- When you are on time with your own deliverable, customer satisfaction is greatly improved.

- When a pipe is installed at a joint, the odds of water leaking around it increase.

- Plumbing systems can be designed and planned easily. They can not only help to make the work process easier, but also reliable.

- As far as pipes go, the possibilities of what could be wrong can only be limited.

Aerator

With the presence of interior waterways, there is more control over how much air gets produced by internal baffles scattered throughout these chambers. It consists of two chambers:

Offset

The offset chamber is put near the high-riser and it slows the flow as it enters. It then enters the fitting, where it breaks up hydraulic plug formations. Its main function is to prevent soil and waste matter from reaching their terminal velocity, to reduce pressure and reduce velocity with breaking up the seal.

Mixing Chamber

This chamber obstructs the horizontal discharge from choking the stack’s cross-sectional area. A separation baffle is used to isolate these two chambers from each other, perpendicular to which a second chamber is installed that prevents cross flow from the contradicting branch inlets.

De-aerator

When it comes to breaking the stack system, the final component is responsible for even distribution of pressure. The hydraulic jump happens when pressure changes significantly at a transition point. One of the drawbacks of the hydraulic jump is that it often ends up blocking your horizontal stack. With Deaerator, we’re able to accomplish two important goals:

- The nose piece helps to reduce the flow velocity right before the transition in the horizontal stack, allowing air and waste to separate in the main chamber itself.

- PRL Pressure Relief Line or PRL is the head of the deaerator that routes from the pressure side to the drain. It has a loop here that accommodates for a “hydraulic jump.”

Think of a high-rise building as a vertical stack of empty bottles. The waste moves through the building along the wall of the stack and spirals downward toward its base so that the center portion is left open air. As long as the airway exists, the pressures will be balanced. But abandon the flow and you’ll see how fast air goes. The faster air goes, the higher the terminal velocity.

Guidelines

- The Aerator should be installed in a vertical plane.Waste pipes that are smaller than the stack size may connect directly to the stack through a sanitary fitting.

- Waste stacks may be combined on the end of a Pressure Relief Line termination point. These stacks shall chain downstream toward the core sewer drain.

- When creating a slope for the building drain, it is suggested that you margin at a rate of one-quarter inch per foot.

Plumbing system and BIM : The advancement

The BIM process helps in building plumbing design drawings and schematics. This makes it easier for you, the engineer, to place and execute stack designs on site. Explore the transformative power of Building Information Modeling in enhancing construction processes through the efficient streamlining of plumbing systems. Discover how this innovative approach optimizes project management, minimizes errors, and maximizes resource utilization, leading to cost-effective and sustainable outcomes. Now the question arises: why is BIM( Building Information Modeling) now essential to the plumbing systems? One of the biggest pros of BIM is that you benefit from reduced clashes within a building, which often plague your project with unnecessary costs and construction delays. The process of streamlining plumbing systems becomes a strategic endeavor, revolutionizing construction with enhanced precision, cost-effectiveness, and seamless collaboration.

- BIM is short for Building Information Modeling. BIM Designing according to the terms established by your clients

- adaptable approach

- Clashes

- The practice behind leading BIM tools

- Working with BIM tools ensures that there are fewer errors and more productivity in the workplace.

- Modern workflow

- Level of detailing, or LOD, is as per international codes.

- Constructability review

Conclusion

With our engineering skills and product knowledge, Sovent System provides specifiers with a new way to model both waste water and venting. Because we can offer specifiers two bonus parameters of information on plumbing fixtures, one will contain the required GPM (Gallons per minute) flow for the standard fixture, while the other will contain the reduced GPM flow amount required. By leveraging Building Information Modeling, the process of streamlining plumbing systems becomes efficient, enhancing construction projects significantly.

Reusing gray water for onsite use when designing a waste system project can help reduce the burden on municipal wastewater treatment plants. The use of BIM minimizes coordination errors with architects and structural engineers, while improving efficiency and building quality. The MEP shop drawings developed through the process strengthen the pre-construction fabrication process.

Follow Milestone PLM Solutions for Mechanical Industry Updates, CAD Tips and Global CAD, CAM & FEA News.

Milestone PLM Solutions with its exclusive delivery center in India is a global CAD, CAM & FEA services outsourcing partner serving the needs of the Mechanical, Millwork and Automotive industry since 2004. MILESTONE focuses on the unique needs of clients and believe in tackling real-life problems with efficiency, smooth and ease.

The MILESTONE team can assist you with Product Design, 3d Modeling, Drafting & detailing, Reverse Engineering, FEA Analysis and more. We support multiple software including AutoCAD, Solidworks, Catia, NX, Inventor, Solidedge & Ansys etc. Our approach is to provide a dedicated team for each customer over ongoing project and deliver the quality output consistently.

With our state of art technology and large talent pool of Engineers, we are developing best in class solutions for our customers across the globe. We align with your culture and values to form unbreakable partnerships and are primed for success with over 100 employees and 150 customers in the US, Europe, India, and Asia.

For more queries regarding any of the above-mentioned topics, feel free to connect with us on our website www.milestonetech.net or contact us on +1-844-598-0005 .