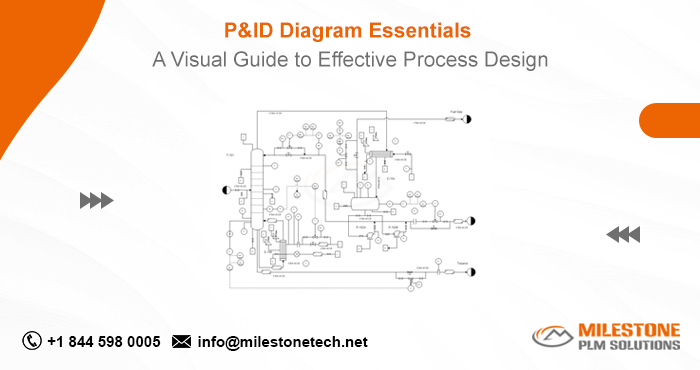

P&ID Diagram Essentials: A Visual Guide to Effective Process Design

Piping and Instrumentation Diagrams, commonly known as P&ID Diagrams, are critical tools in the field of process engineering. These diagrams serve as a visual representation of the entire process flow, showing the piping, equipment, instrumentation, and control systems involved in a process. A well-crafted P&ID Diagram is essential for designing, operating, and maintaining complex industrial systems. This blog provides a comprehensive guide to understanding P&ID Diagrams, highlighting their importance, essential components, and best practices for creating effective process designs.

Understanding the Importance of P&ID Diagrams

P&ID Diagrams are more than just technical drawings; they are the blueprint for process control and instrumentation in various industries, including oil and gas, chemical, pharmaceutical, and power generation. These diagrams offer a detailed view of how the process should function, ensuring that all components are correctly connected, and that the system operates safely and efficiently.

The primary purposes of a P&ID Diagram include:

Design and Development: P&ID Diagrams are used during the design phase to plan the layout and configuration of process systems. They help engineers visualize the entire process, identify potential issues, and optimize the design.

Operational Guidance: Operators use P&ID Diagrams to understand the process flow, control systems, and safety mechanisms. These diagrams serve as a reference for operating the system and troubleshooting any issues that arise.

Maintenance and Safety: P&ID Diagrams are essential for maintenance teams to identify equipment and instrumentation locations, understand control loops, and implement safety procedures. They also play a crucial role in safety audits and hazard analysis.

Key Components of a P&ID Diagram

A P&ID Diagram is composed of several key components, each represented by standardized symbols. Understanding these components is crucial for interpreting and creating accurate P&ID Diagrams.

Piping

Piping is the backbone of any process system, and it is depicted using various line types and symbols on a P&ID Diagram. Common piping symbols include:

- Solid Lines: Represent process piping that carries fluids or gases between equipment and instruments.

- Dashed Lines: Indicate lines that are not physically present, such as electrical signals or control systems.

- Arrows: Show the direction of flow within the piping, which is crucial for understanding the process flow.

- Pipe Size Labels: Indicate the diameter of the piping, ensuring that the correct size is used for the required flow rate and pressure.

Equipment

Piping is the backbone of any process system, and it is depicted using various line types and symbols on a P&ID Diagram. Common piping symbols include:

- Solid Lines: Represent process piping that carries fluids or gases between equipment and instruments.

- Dashed Lines: Indicate lines that are not physically present, such as electrical signals or control systems.

- Arrows: Show the direction of flow within the piping, which is crucial for understanding the process flow.

- Pipe Size Labels: Indicate the diameter of the piping, ensuring that the correct size is used for the required flow rate and pressure.

Instrumentation

Instrumentation symbols represent the devices used to measure and control the process. These symbols are essential for ensuring that the process operates within the desired parameters. Key instrumentation symbols include:

- Pressure Gauges: Shown as a circle with the letter “P” inside, indicating a device that measures pressure.

- Temperature Sensors: Represented by a circle with the letter “T” inside, showing a device that measures temperature.

- Flow Meters: Depicted by a circle with the letter “F” inside, indicating a device that measures flow rate.

- Level Indicators: Shown as a circle with the letter “L” inside, representing a device that measures liquid level in a tank or vessel.

Valves

Valves are crucial for controlling the flow of fluids and gases in the process. They are represented by various symbols depending on the type of valve. Common valve symbols include:

- Gate Valve: Depicted by a rectangle with a line through the center, representing a valve that controls flow by lifting a gate.

- Globe Valve: Shown as a circle with an “X” inside, indicating a valve that regulates flow by a disc movement.

- Check Valve: Represented by a triangle pointing in the flow direction with a line across it, showing a valve that allows flow in one direction only.

- Ball Valve: Depicted by a circle with a solid line, indicating a valve that controls flow with a rotating ball.

Control Systems

Control systems are depicted on a P&ID Diagram to show how the process is monitored and controlled. These symbols include:

- Controllers: Shown as circles with specific letters, such as “PC” for pressure control or “TC” for temperature control.

- Control Loops: Represented by lines connecting the controllers to the instruments and valves they control.

- Alarms: Indicated by specific symbols, showing where alarms are set to trigger in case of abnormal process conditions.

Best Practices for Creating Effective P&ID Diagrams

Creating an accurate and effective P&ID Diagram requires attention to detail and adherence to industry standards. Here are some best practices to follow:

- Use Standardized Symbols : Always use standardized symbols as defined by organizations like ISO and ISA (International Society of Automation). This ensures consistency and makes the diagram understandable to all stakeholders.

- Label Clearly : Label all components, including pipes, equipment, and instruments, with their respective names, sizes, and specifications. Clear labeling reduces the risk of misinterpretation.

- Maintain Simplicity : While it’s essential to include all necessary details, avoid overcomplicating the diagram. A cluttered P&ID Diagram can be difficult to read and understand. Keep the layout simple and logical.

- Ensure Accuracy : Double-check all symbols, labels, and connections to ensure they accurately represent the process. Inaccuracies can lead to operational issues and safety risks.

- Regular Updates : P&ID Diagrams should be regularly updated to reflect any changes in the process design. Outdated diagrams can lead to incorrect operations and maintenance procedures.

Conclusion

A well-designed P&ID Diagram is a powerful tool in process engineering, providing a clear and detailed representation of the entire process system. By understanding the essential components and following best practices, engineers can create effective P&ID Diagrams that enhance the design, operation, and safety of industrial processes.

Whether you are involved in the design phase, operation, or maintenance of a process system, mastering P&ID Diagrams is crucial for ensuring that the system functions efficiently and safely. As you continue to work with P&ID Diagrams, remember that these diagrams are more than just drawings—they are the key to effective process design and control.

Follow Milestone PLM Solutions for Mechanical Industry Updates, CAD Tips and Global Mechanical News.

Milestone PLM Solutions with its exclusive delivery center in India is a global CAD, CAM & FEA services outsourcing partner serving the needs of the Mechanical, Millwork and Automotive industry since 2004. MILESTONE focuses on the unique needs of clients and believes in tackling real-life problems with efficiency, smooth and ease.

The MILESTONE team can assist you with Product Design, 3d Modeling, Drafting & detailing, Reverse Engineering, FEA Analysis and more. We support multiple software including AutoCAD, SolidWorks, Catia, NX, Inventor, Solidedge & Ansys etc. Our approach is to provide a dedicated team for each customer over ongoing project and deliver the quality output consistently.

With our state of art technology and large talent pool of Engineers, we are developing best in class solutions for our customers across the globe. We align with your culture and values to form unbreakable partnerships and are primed for success with over 100 employees and 150 customers in the US, Europe, India, and Asia.

You can email us at info@milestonetech.net and can log in to our website www. milestonetech.net to know more about our services and our work portfolio or contact us on +1-844-598-0005